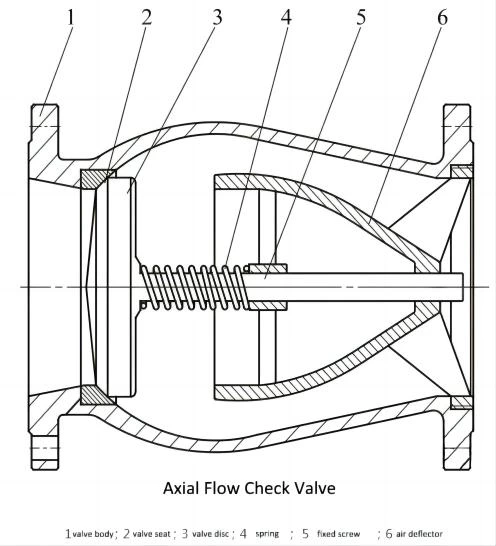

FVF Casting Axial Flow Slient Check Valve

Product Description

FVF Axial flow check valve in addition to the function of the general check valve, it is also designed with a shock absorber spring, its hard seal with soft seal of the combined seat sealing structure has noise reduction, shock absorption effect, easy to users on-site maintenance, unique axial flow shuttle structure has the advantages of small flow resistance, large flow coefficient, small size, etc. It is the preferred valve for domestic and foreign oil and gas gathering pipeline system, especially for the outlet of oil pump. It is suitable for oil, gas, water slurry and H2S+C02 acid corrosive medium and other pipeline system, control medium countercurrent use.

Specifications

- 1.Size: 2"--40"

- 2.Pressure:150L-2500LB

- 3. Design: API6D, BS, DIN, JIS

- 4. Material: F304, F316, F304L, F316LWCB, WCC, LCB, WC6

Product Features

- 1. The product is composed of valve body, guide body, axially moving disc and spring parts. The product can effectively prevent medium backflow. Ensure pipeline safety.

- 2. The use of high performance spring material HT/INCONELX-750, with excellent corrosion resistance, oxidation resistance and excellent mechanical properties, to ensure the spring long-term working conditions, running state.

- 3. Rapid opening and closing, highly reliable preloaded spring enables disc to respond quickly to fluid pressure changes.

- 4. The valve adopts alloy steel surfacing sealing face, wear resistance, corrosion resistance, long service life.