BS 5352 Integral Flange Forged A105N Gate Valve Class 800

- Place of Origin:

- Wenzhou,China

- Packing:

- Suitable Packing for Sea/Air Transport

- Medium:

- Water,oil,gas,etc.

- Connection:

- Flange

- Pressure:

- PN16-PN42,CLASS 150-2500

- Temperature:

- -29℃~425℃

FVF BS 5352 Integral Flange Forged A105N Gate Valve Class 800

- FVF Integral Flange Forged Gate Valve mainly suitable for the pipelines of various systems of thermal power stations, cutting or connecting the pipeline medium. Widely used in oil pipelines.

- It is suitable for small diameter pipes with pressure 1.6~42.0Mpa(Class 150~2500) and temperature range -29°C~425 °C(Carbon Steel), -29°C~500 °C( Stainless Steel).

- Compared with other valve products, the integral flange forged steel valve is characterized by high temperature and high pressure and unique self-sealing design. The higher the pressure, the more reliable the seal. Due to the special technical characteristics and working conditions, the products also form features that cannot be replaced by other products.

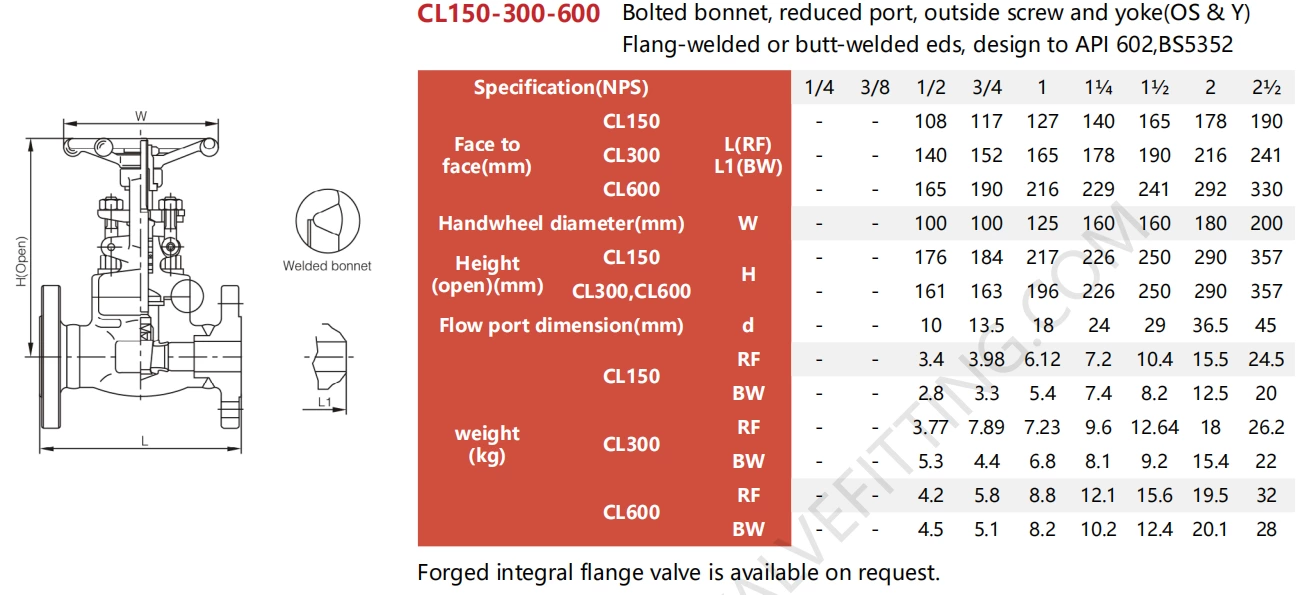

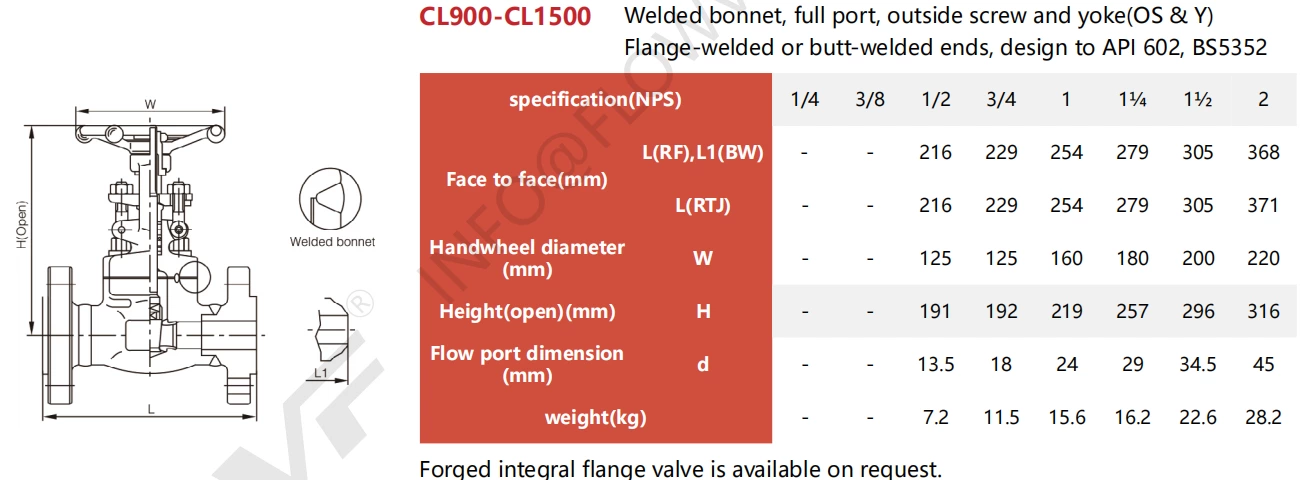

Product Parameter

Application standards

1. Design and manufacture conform to API 602, BS 5352, ASME B16.34

2. Connection ends conform to:

Socket welded ends conform to ANSI B16.11, JB/T1751

Screw ends conform to ANSI B1.20.1, JB/T7306

Butt-welded ends conform to ANSI B16.25, JB/T12224

Flange ends conform to ANSI B16.5, JB79

3. Test and inspection conform to: API 598, GB/T13927,JB/T9092

4. Structure features:

Bolted bonnet, outside screw and yoke

Welded bonnet , outside screw and yoke

5. Materials conform to ANSI/ASTM

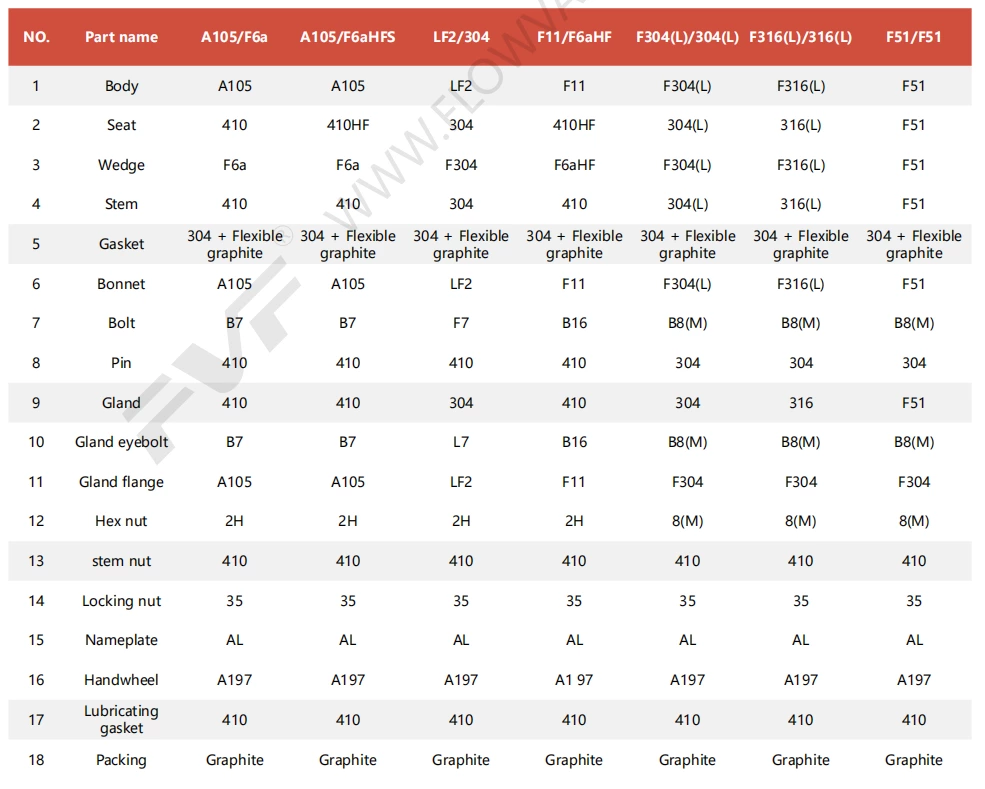

6. Main materials:A105, LF2, F5, F11, F22, F304(L, F316(L),F347, F321, F51, Monel, Alloy 20# etc.

Carbon steel temperature-pressure rate

CL150-285P.S.l @100℉ CL300-740P.S.l @100℉ CL600-1480P.S.l @100℉ CL800-1975P.S.I @100°F CL1500-3705P.S.l @100℉

Material List of Main Parts

Product Drawing