BS 5352 Bellow Sealed A105N Forged Globe Valve Class 800 Class 1500

- Place of Origin:

- Wenzhou,China

- Packing:

- Suitable Packing for Sea/Air Transport

- Material:

- A105; LF2; F5; F11; F22; F304(L); F316(L);F347; F321; F51; Monel; Alloy 20# etc.

- Connection:

- Socket Weld

- Pressure:

- 150LB-1500LB

- Temperature:

- -29°C~425 °C

FVF BS 5352 Bellow Sealed A105N Forged Globe Valve Class 800 Class 1500

- FVF Bellows Sealed Globe Valve adopts advanced foreign technology, using double bellows design, welded to the valve stem to maintain stable operating performance, avoid the valve vibration caused by valve plug vibration.

- In particular chemical processes the fluids in the pipes are often toxic, radioactive and hazardous. Bellow sealed valves are used to prevent leakage of any toxic chemical to the atmosphere.

- At high temperature, the stem does not touch the medium to ensure zero leakage of the stem. At the same time ensure enough strength and toughness, can switch tens of thousands of times.

- The bellow can be supplied in different materials like 316Ti, 321, C276 or Alloy 625. Body material can be selected from all available materials.

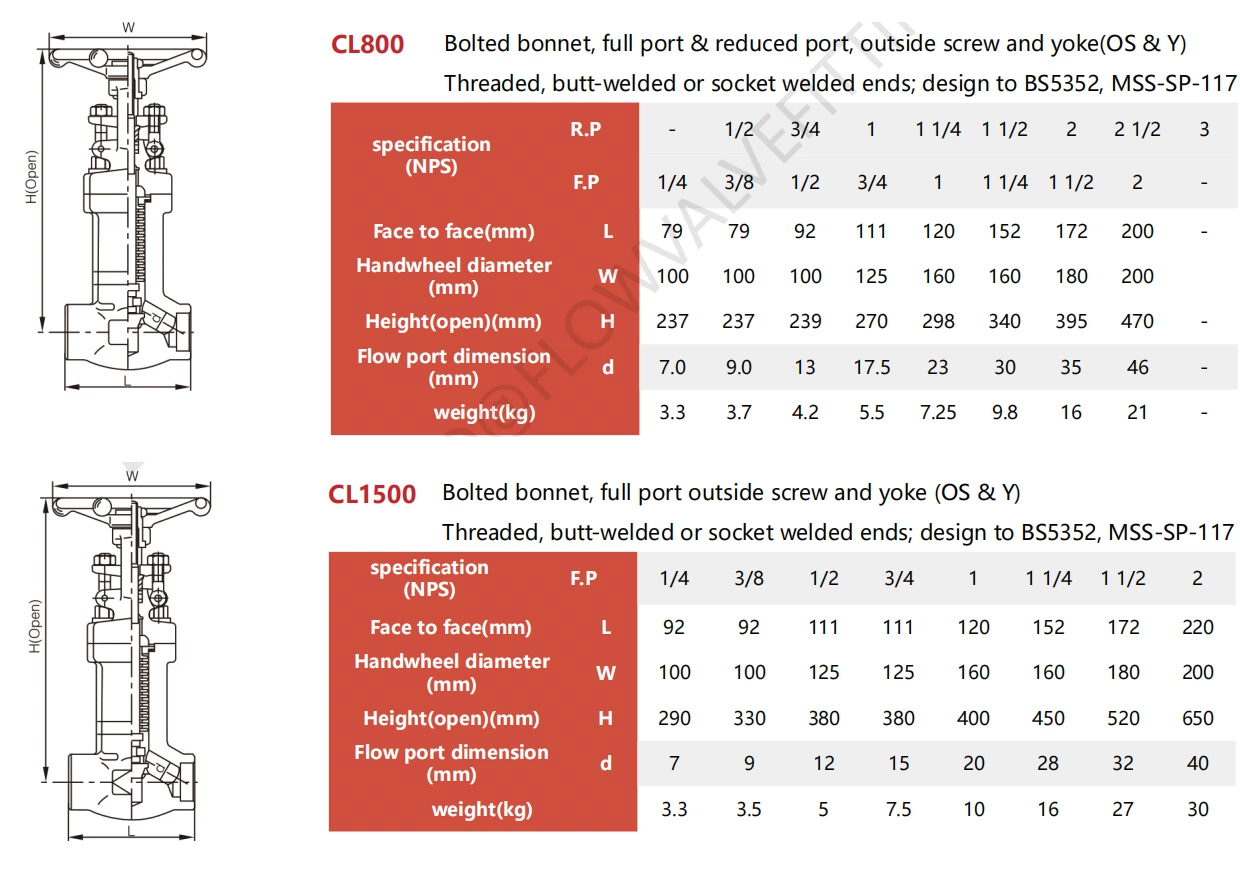

Product Parameter

Application standards

1. Design and manufacture conform to: BS5352; MSS-SP-117

2. Connection ends conform to:

Socket welded ends conform to ANSI B16.11, JB/T1751

Screw ends conform to ANSI B1.20.1, JB/T7306

Butt-welded ends conform to ANSI B16.25, JB/T12224

Flange ends conform to ANSI B16.5, JB79

3. Test and inspection conform to: API598,GB/T13927,JB/T9092

4. Structure features:

Bolted bonnet, outside screw and yoke

Welded bonnet, outside screw and yoke

5. Materials conform to ANSI/ASTM

6. Main materials: A105, F304(L), F316(L), F347, F321

7. Bellow materials: SS304, SS321, SS316, Inconel 625, Hastelloy C 276, Monel etc.

Carbon steel temperature-pressure rate

CL150-285P.S.l @100℉ CL300-740P.S.l @100℉ CL600-1480P.S.l @100℉ CL800-1975P.S.I @100°F CL1500-3705P.S.l @100℉

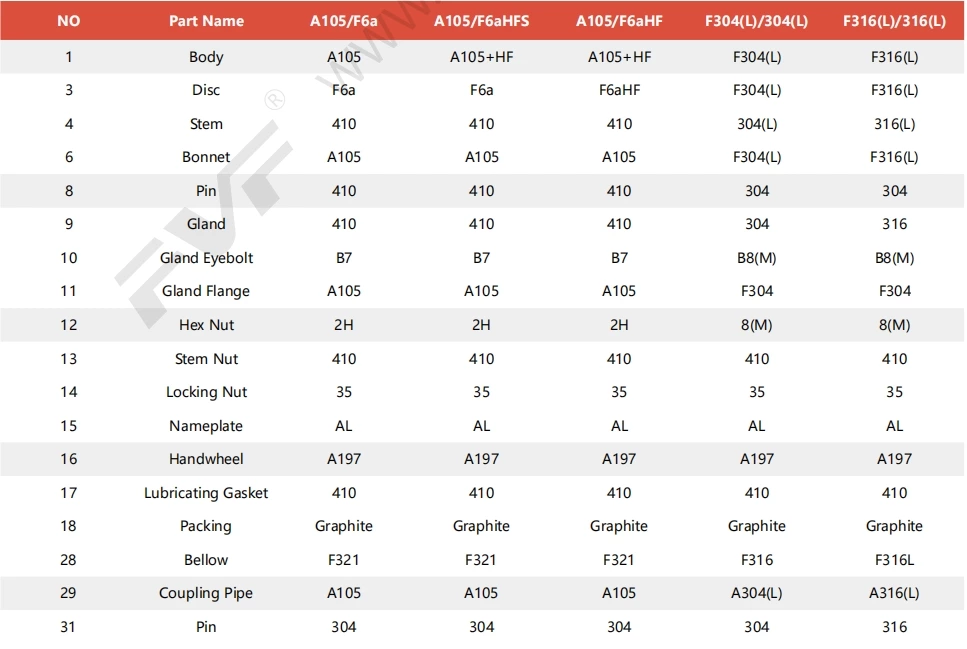

Material List of Main Parts

Product Drawing